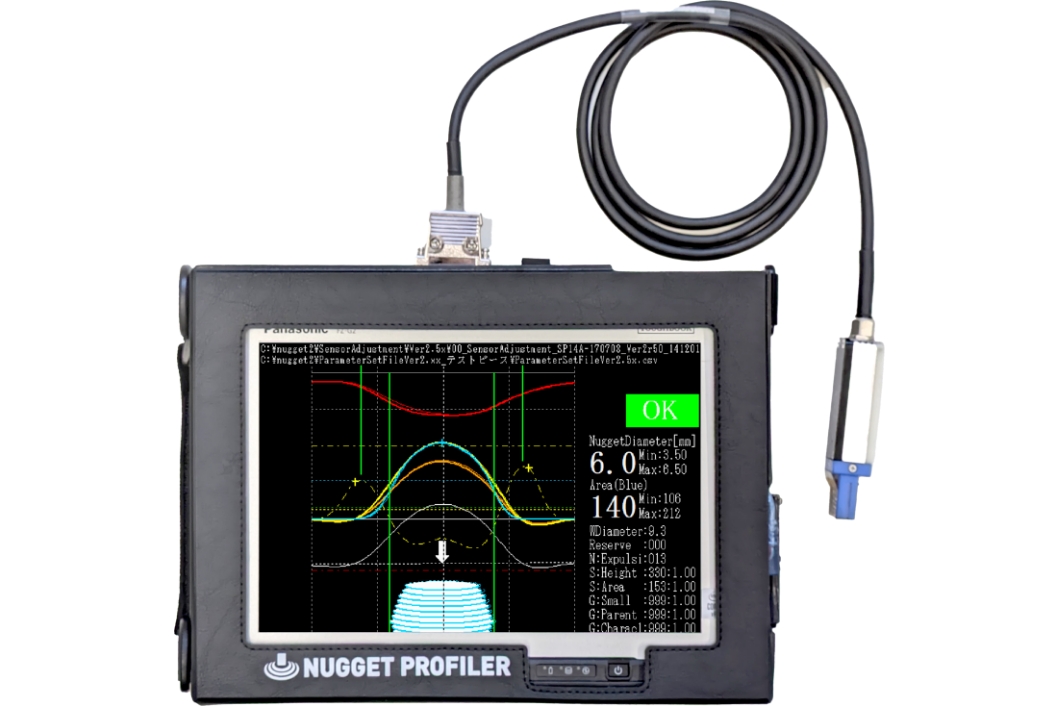

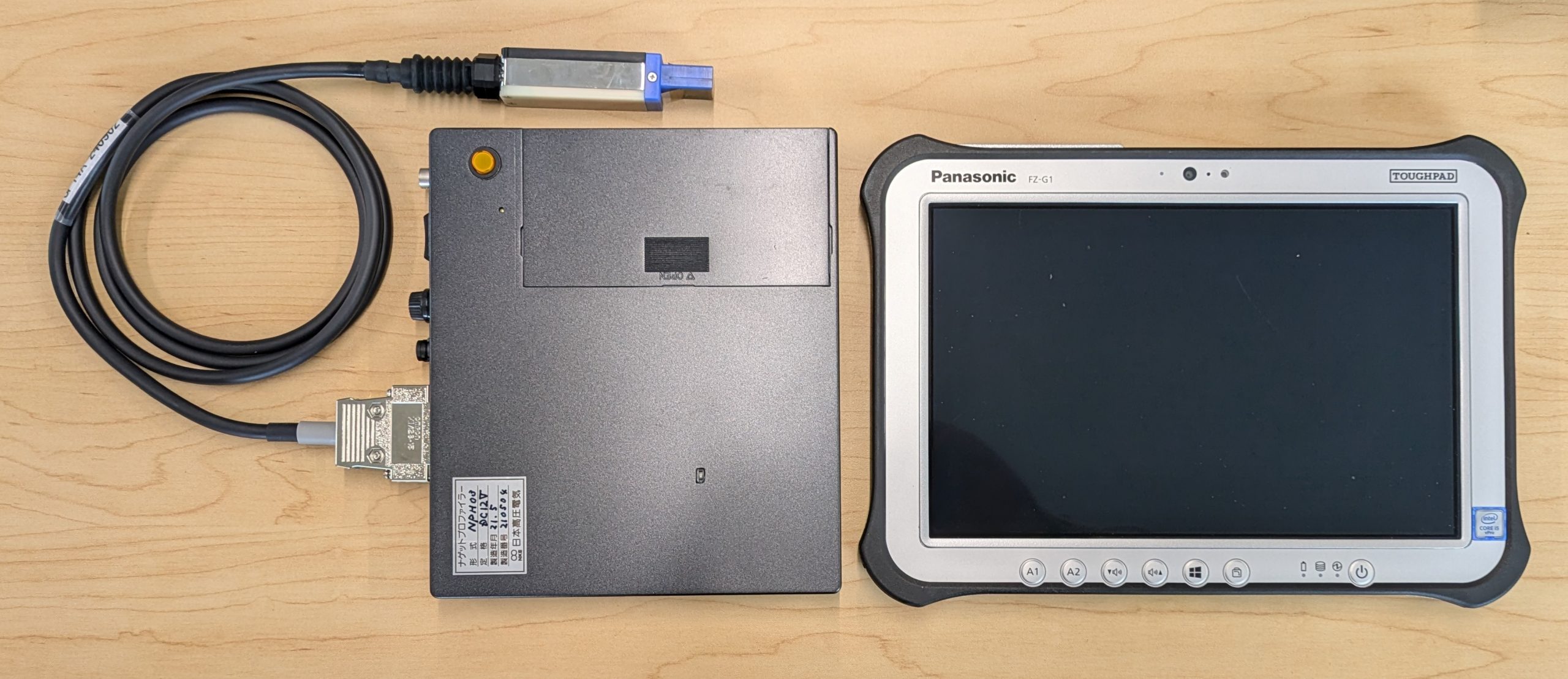

NUGGET

PROFILER

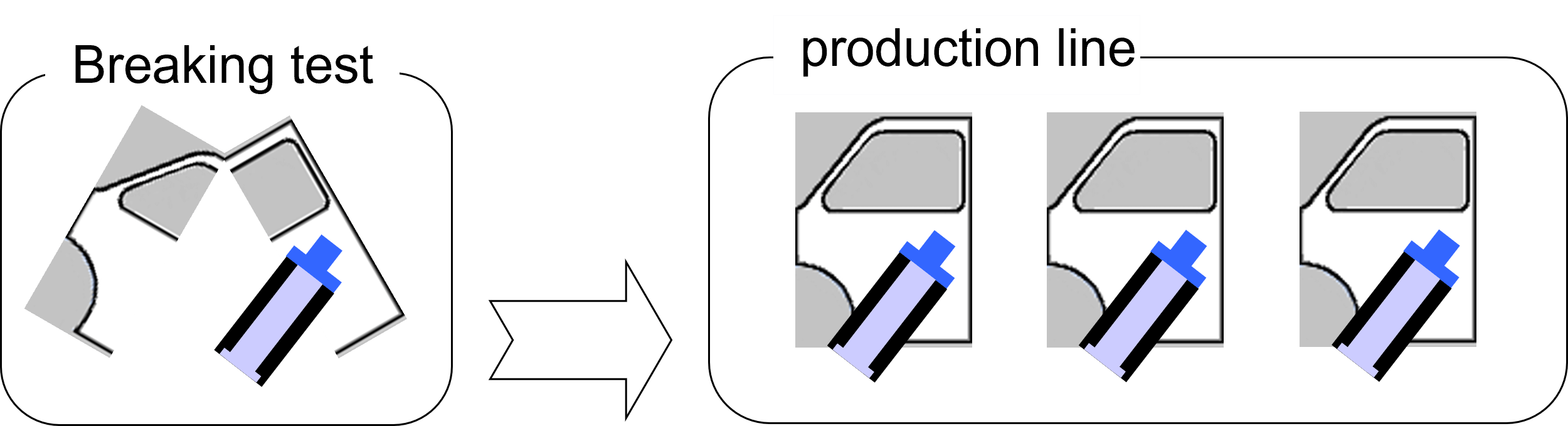

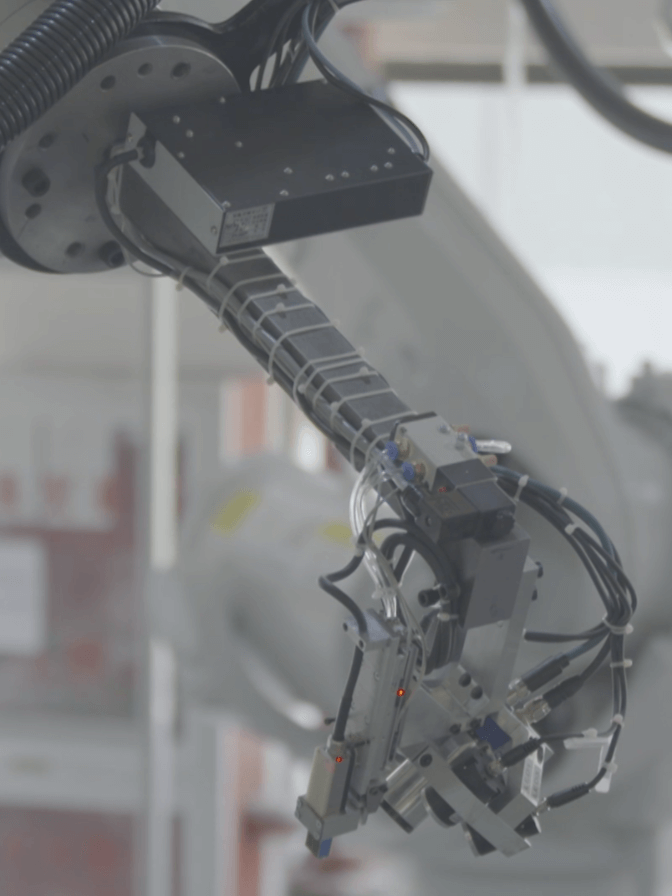

Non-destructive inspection equipment

for spot welding using magnetism.

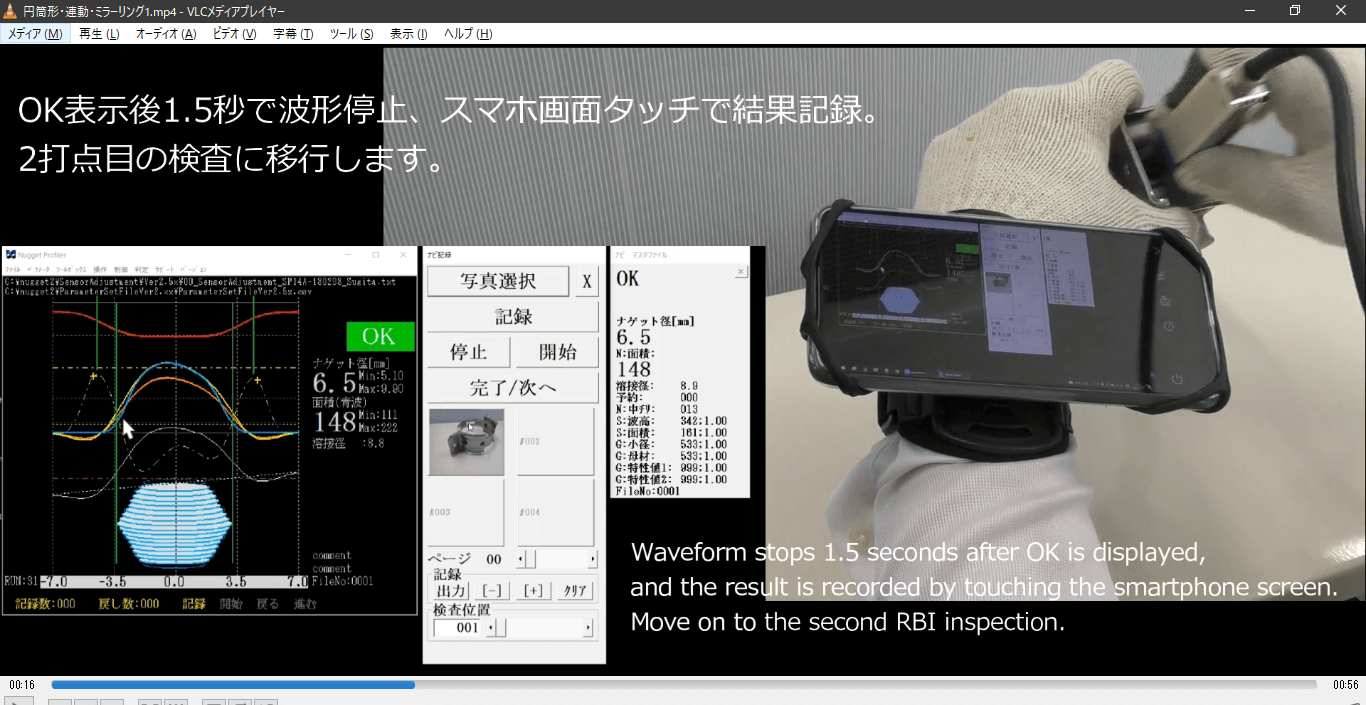

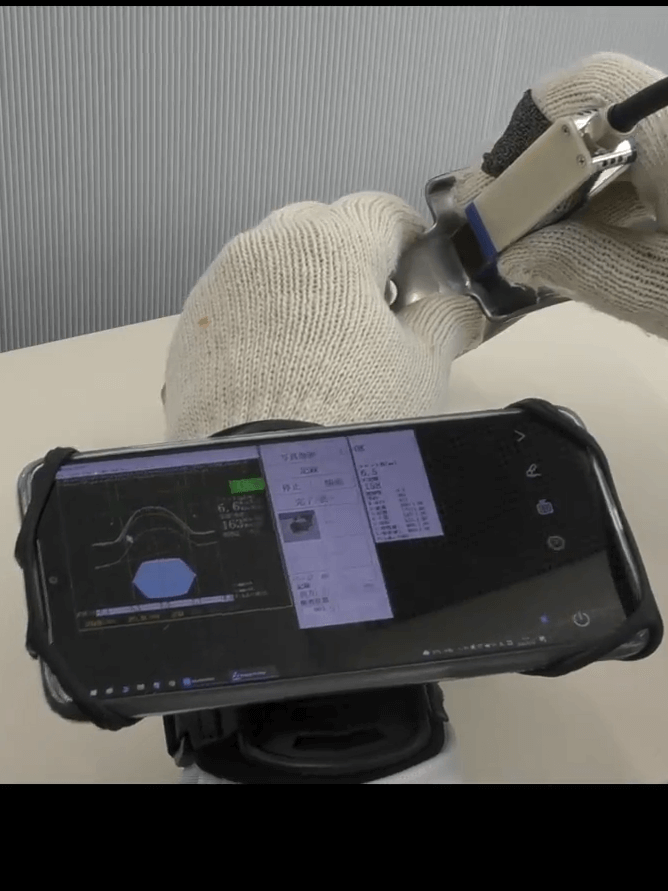

It is an inspection equipment which can quantify the nugget of spot welding easily.

This device uses magnetism and, unlike ultrasonic systems, does not require the application of gel during inspection. Inspection can be performed in dry conditions.

Oil on the product surface does not affect the inspection.